is the Most Versatile Blasting Equipment Available

is the Most Versatile Blasting Equipment Available

With technology, you can adjust the air pressure and abrasive flow separately, allowing you to clean substrates that other abrasive blasters would damage or destroy. Turn the pressure down to 25 psi for cleaning antique metal, wood, fiberglass, soft stone, stucco, and concrete. Crank it up to 170 psi to cut through heavy rust and thick coatings and blast steel down to white metal. is ideal for restoration work, mold remediation and removing graffiti, with ample power to cut through the toughest coatings, antifouling and sludge. The JR300 and SR600 can blast wet or dry for year round contracts.

works with any media that sinks in water, including garnet, slag, grit, sand, soda, glass, and more.

works with any media that sinks in water, including garnet, slag, grit, sand, soda, glass, and more.

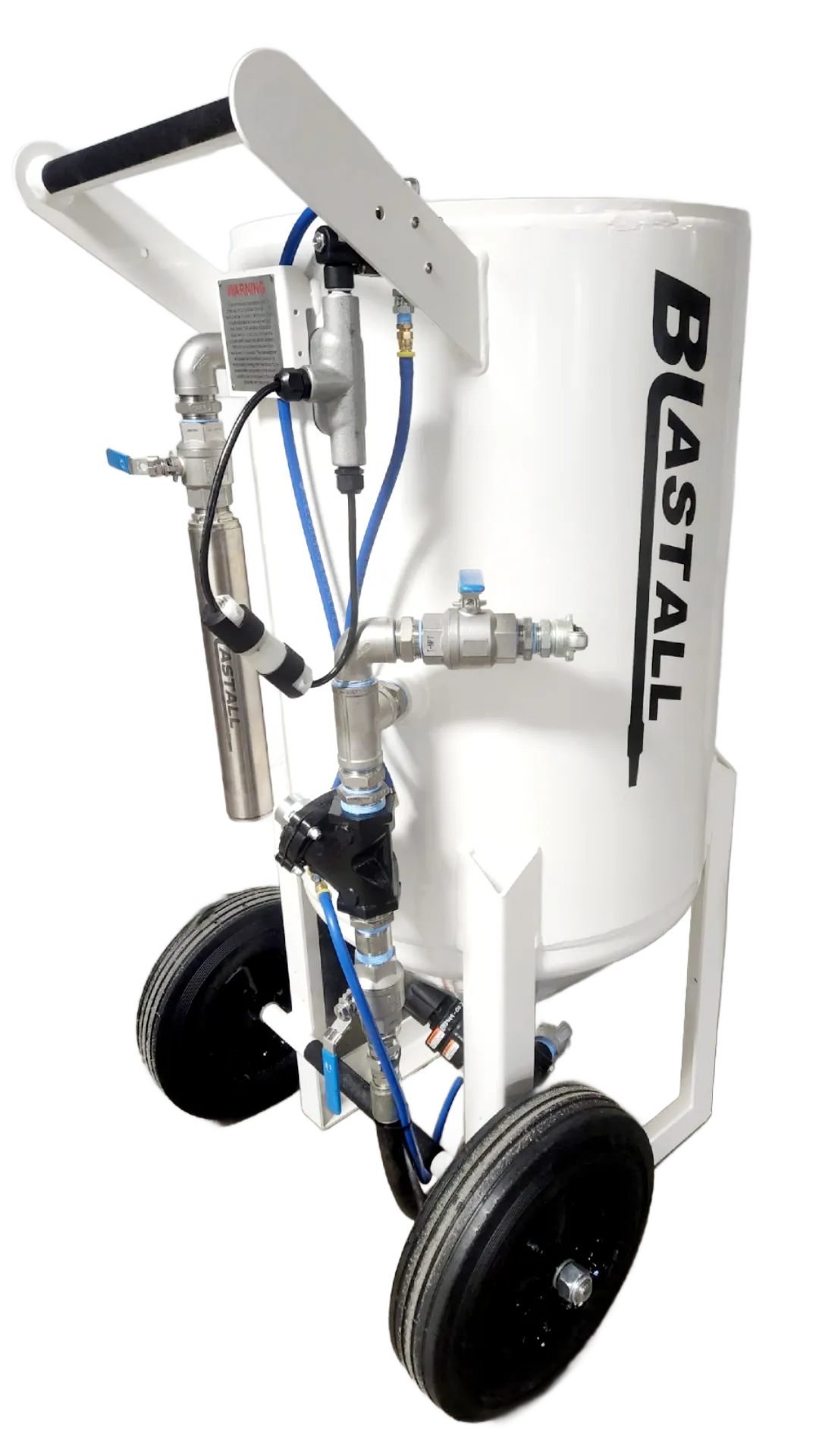

JR300

Compact, portable blast equipment.

SR600

A fully loaded, high production system.

GP2000

High Capacity, fully loaded high production system.

Blastall 6.5ft³ DryPot

A fully loaded, high production system.

Blastall 3.5ft³ DryPot

A fully loaded, portable, high production dry blast system.

About Blastall

Blastall has been engineering and manufacturing equipment that pumps, meters, mixes, and dispenses liquids. They are the fluid-handling experts, providing solutions to over 20 industries. Blastall manufactures JR300 & SR600 to world-class standards, with quality parts, rigorously testing each machine prior to shipping to ensure it performs to specifications in the field. Blastall products are sold and supported by trained Blastall distributors, providing local support wherever the job takes you.

Find us on Facebook and Youtube!

Blastall Equipment & Supply 1472 Highway 3 East Dunnville, ON Canada N1A 2W7